Optical Characteristics

| Micro cable model | GCYFY--xx F | |||||||||

| Number of fiber cores | 24 | 36 | 48 | 60 | 72 | 96 | 144 | 216 | 288 | |

| Loose tube quantity | 2 | 3 | 4 | 5 | 6 | 8 | 12 | 18 | 24 | |

| Filling rope quantity | 4 | 3 | 2 | 1 | 0 | 0 | 0 | 0 | 0 | |

| Maximum fiber loading capacity of a single loose tube | 12 | |||||||||

|

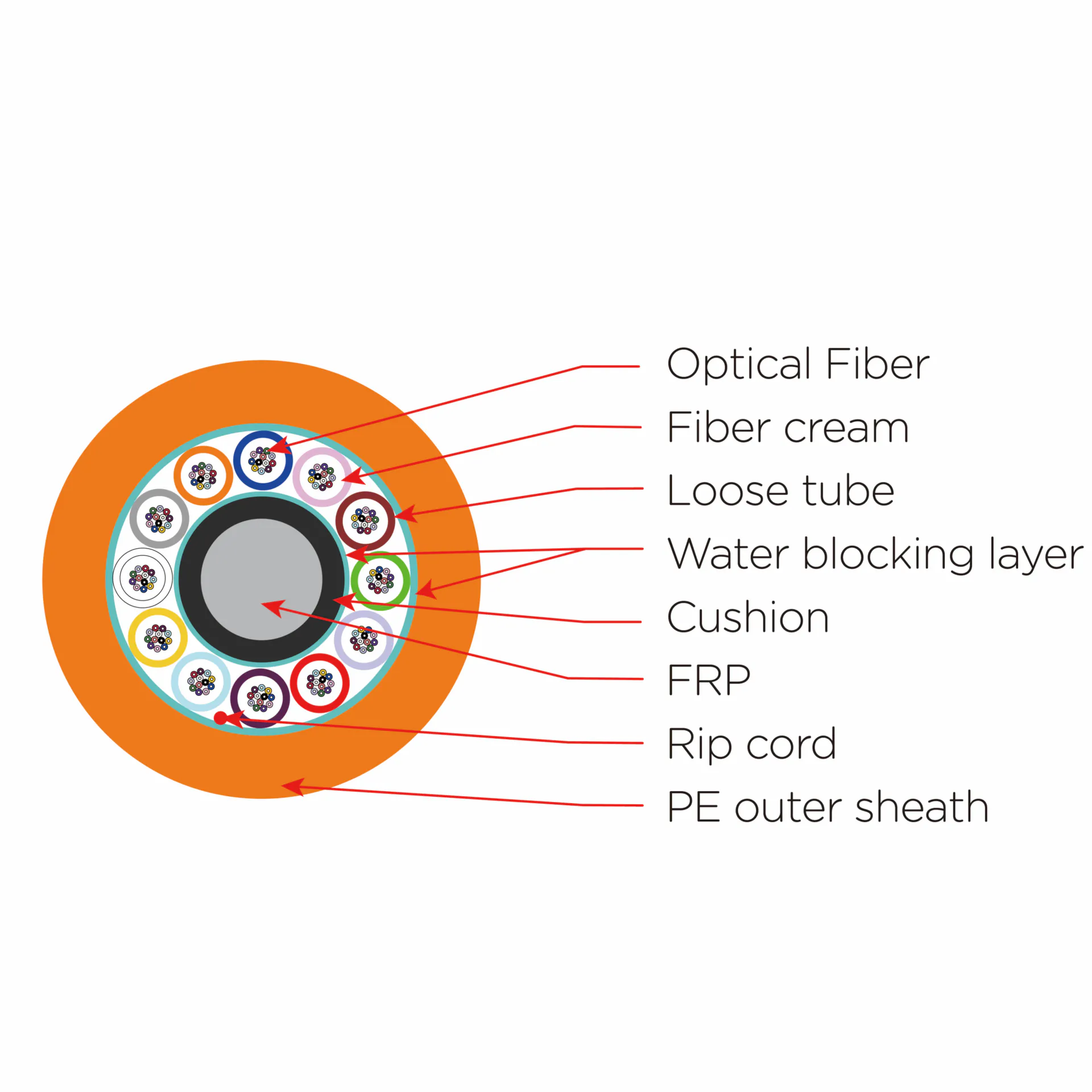

Water blocking method |

FRP or PE cushion | Water-blocking yarn blocks water | ||||||||

| Cable core surface | Water-blocking aramid yarn water-blocking | |||||||||

| PA12 outer sheath thickness | Nominal: 0.50mm, Average: 0.45mm, Minimum: 0.40mm | |||||||||

| Nominal outer diameter | 5.5mm | 6.3mm | 7.8mm | 7.8mm | 9.3mm | |||||

| Approximate weight | 27kg/km | 40kg/km | 55kg/km | 55kg/km | 78kg/km | |||||

| Maximum pulling force | 500N | 1000N | 1000N | 500N | 1000N | |||||

| Maximum crushing force | 800N/100m | |||||||||

| Allowed minimum static, dynamic bending radius | 10 times/20 times the outer diameter of the optical cable | |||||||||

| Fiber optic cable attenuation (single-mode fiber) | 1310nm/1550nm≤0.35/0.22dB/km | |||||||||

| Optical cable life (estimated) | 10 times/20 times the outer diameter of the optical cable | |||||||||

| Applicable temperature range | Storage -30~+60℃; Installation -10~+40℃; Operation -20~+50℃ | |||||||||

| Optical cable life (estimated) | 25 years | |||||||||

Air blowing performance

| Test Equipment | Pipe models suitable for air delivery and corresponding typical air delivery lengths |

|||

| Payment: PR-140, MiniJet-400, etc., air pressure: 15bar | Number of fiber cores | Microtube model

8.0/10.0mm |

Microtube model 10.0/12.0mm |

Microtube model

12.0/14.0mm |

| 24~72 cores | 1500m | 2000m | / | |

| 96 cores | 1500m | 2000m | / | |

| 144 cores | / | 1500m | 2000m | |

| 216 cores | / | 1200m | 1600m | |

| 288 cores | / | / | 1500m | |

Features

Features

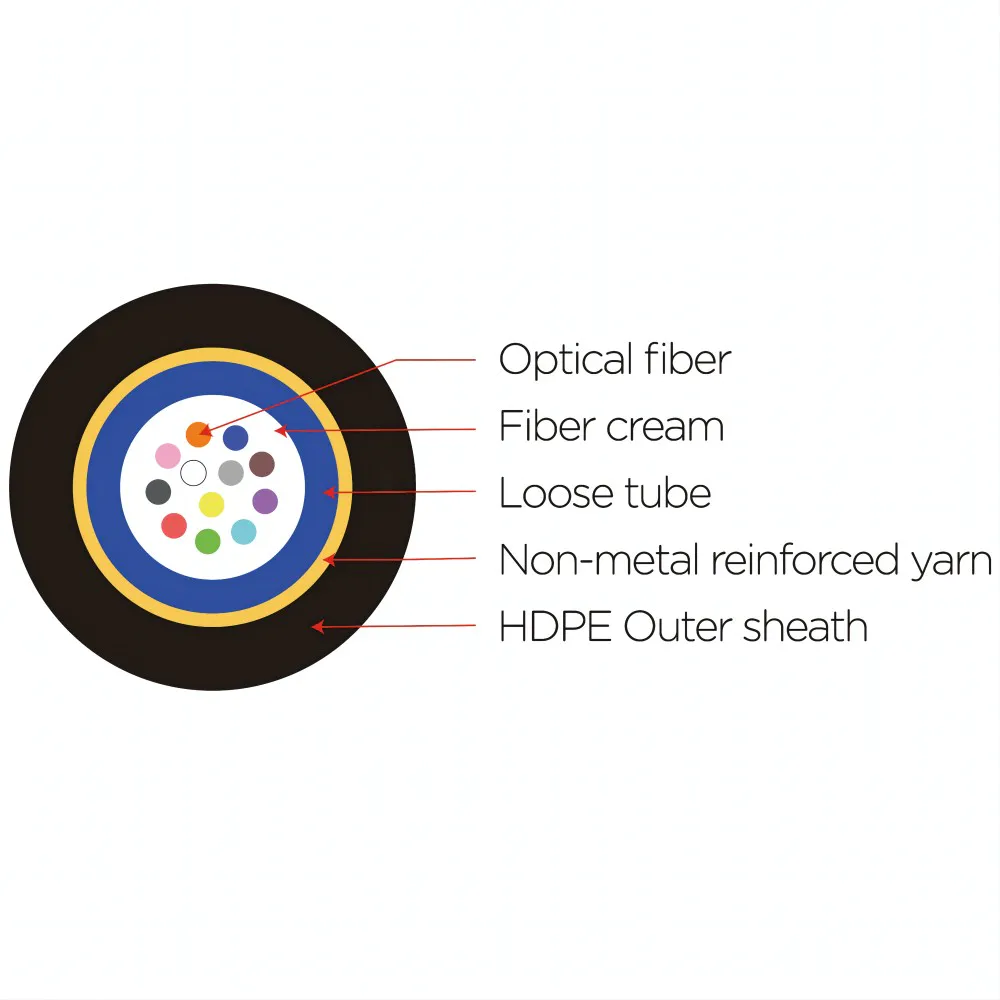

Structural optimization design, with the best fiber capacity;

The remaining length of the optical fiber is precisely controlled and the performance of the optical cable is stable;

Dry cable core blocks water, is low-carbon and environmentally friendly;

Innovative design of the sheath surface enhances air-blowing performance.

Application

Air blowing installation

Core network

Metropolitan Area Network (MAN)

Access network

Backbone network

Local Area Network (LAN)

FTTx network

Data center

5G

Advantages of Carefiber

Good Aramid yarn has excellent tensile performance.

Fast delivery,200km ADSS cable regular production time of about 10 days

Can using glass yarn instead of aramid to anti-rodent

Packge Method

Multiple packaging options are available